How to design a circular product: R-strategies and Cradle to Cradle Certified®

The so-called R-Strategies are widely known as design strategies for circular product design. So, what does it take to successfully apply these strategies to your product life cycle when you intend to work towards Cradle to Cradle Certified®?

When we talk about the R-Strategies, we refer to five key approaches to product circularity that can either be used independently or in combination with each other. These are known as: Reuse, Repair, Refurbish, Remanufacture, and Recycle.

The Cradle to Cradle Certified® Product Standard is the leading methodology used globally by brands, designers and manufacturers to make products for the circular economy. How do the popular R-Strategies fit into the Cradle to Cradle Certified methodology, and more specifically in its Product Circularity category? This article sets out to answer that question.

Some basics:

Product Circularity in the Cradle to Cradle Certified® Product Standard

Product Circularity is one of the five categories of the Cradle to Cradle Certified® Product Standard, next to Material Health, Clean Air & Climate Protection, Water & Soil Stewardship, and Social Fairness. Cradle to Cradle Certified products are holistically assessed across these five categories and receive an achievement level (Bronze, Silver, Gold, Platinum) based upon their performance in each category. In the Standard, the Product Circularity category is built on the pillars of Circular Sourcing, Circular Design and Circular Systems. In the following paragraphs, we explore the requirements that companies need to meet within each of these pillars.

Circular Design. For a product to achieve Cradle to Cradle Certified Bronze level, in this pillar companies need to demonstrate that they are (at least) involved in a circularity education initiative aimed at gaining an understanding of relevant cycling infrastructure development. As the levels go up, the requirements of the Standard become progressively stricter. For example, to achieve Gold level, companies need to demonstrate that they have initiated one or more circular design opportunities and innovations such as:

Increased end-of-use cycling

Greater engagement with users for end-of-use cycling

Prolonged use of the product

Decreased need to extract and produce virgin materials.

Circular Systems. For the Bronze level of this pillar, companies must have defined their intended biological or technical cycling pathways for the product and its materials, and have created a plan to address challenges with the cycling infrastructure at the end of the product’s first use. Potential cycling partners must also be identified. For Gold and Platinum levels, companies need to have an active cycling system in place. Next to this, circularity data and cycling instructions must be publicly available.

Circular Sourcing. The demand for circularly sourced materials must be increased as a result of the increased use of cycled or renewable materials in the product, helping to close the loop and advance the circular economy. Negative impacts of virgin material use also need to be minimized.

The Standard specifies two main criteria for circular sourcing: the percentage of cycled or renewable content, and the uptake of post-consumer or responsibly sourced renewable content. For the former, companies need to select commonly cycled product and material types and incorporate a minimum percentage of cycled and/or renewable content into the product at Bronze level. At Gold level, that percentage needs to be consistent with industry leaders. Regarding the latter, at Gold level, companies need to incorporate either post-consumer recycled or responsibly sourced renewable content.

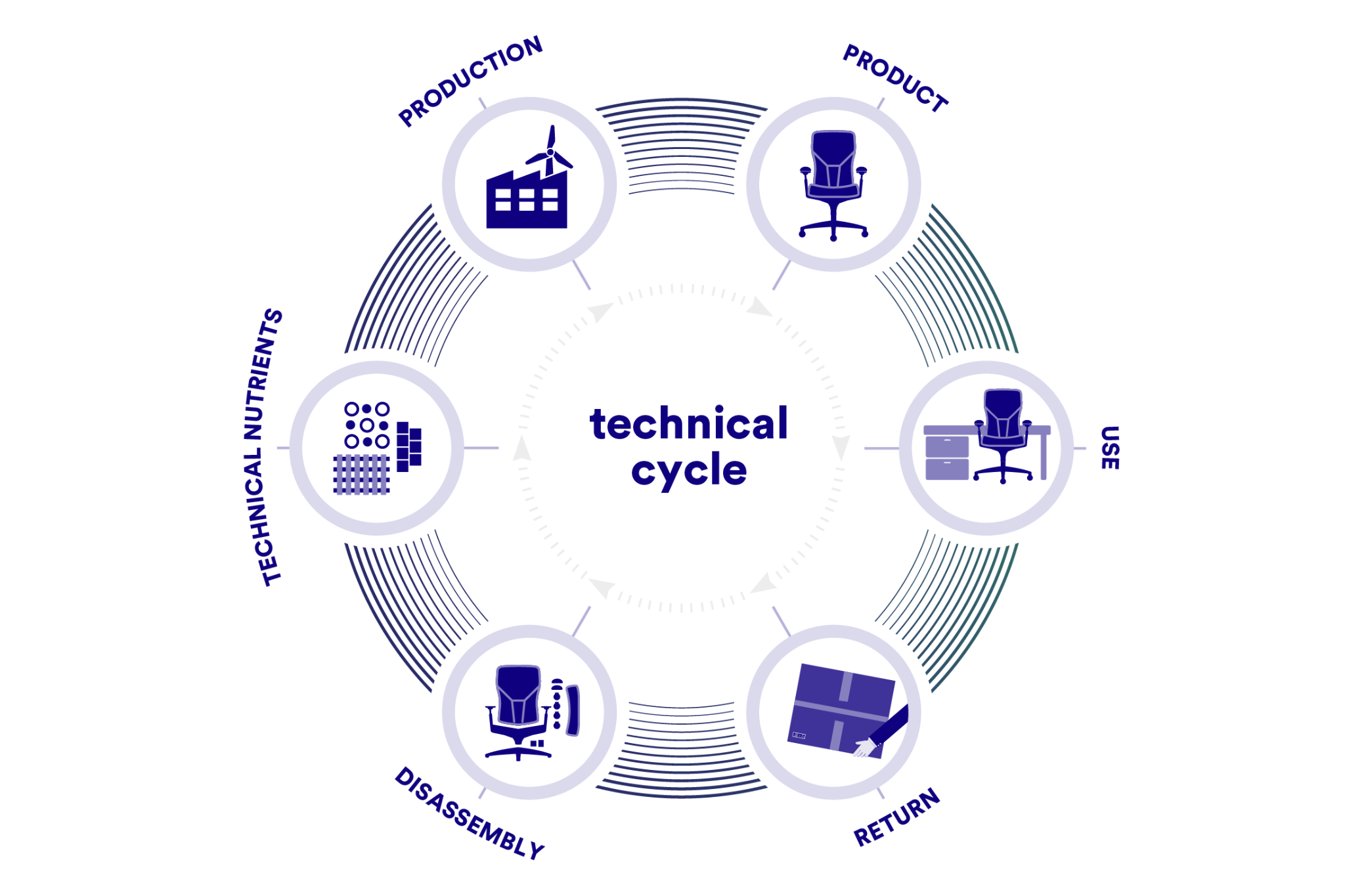

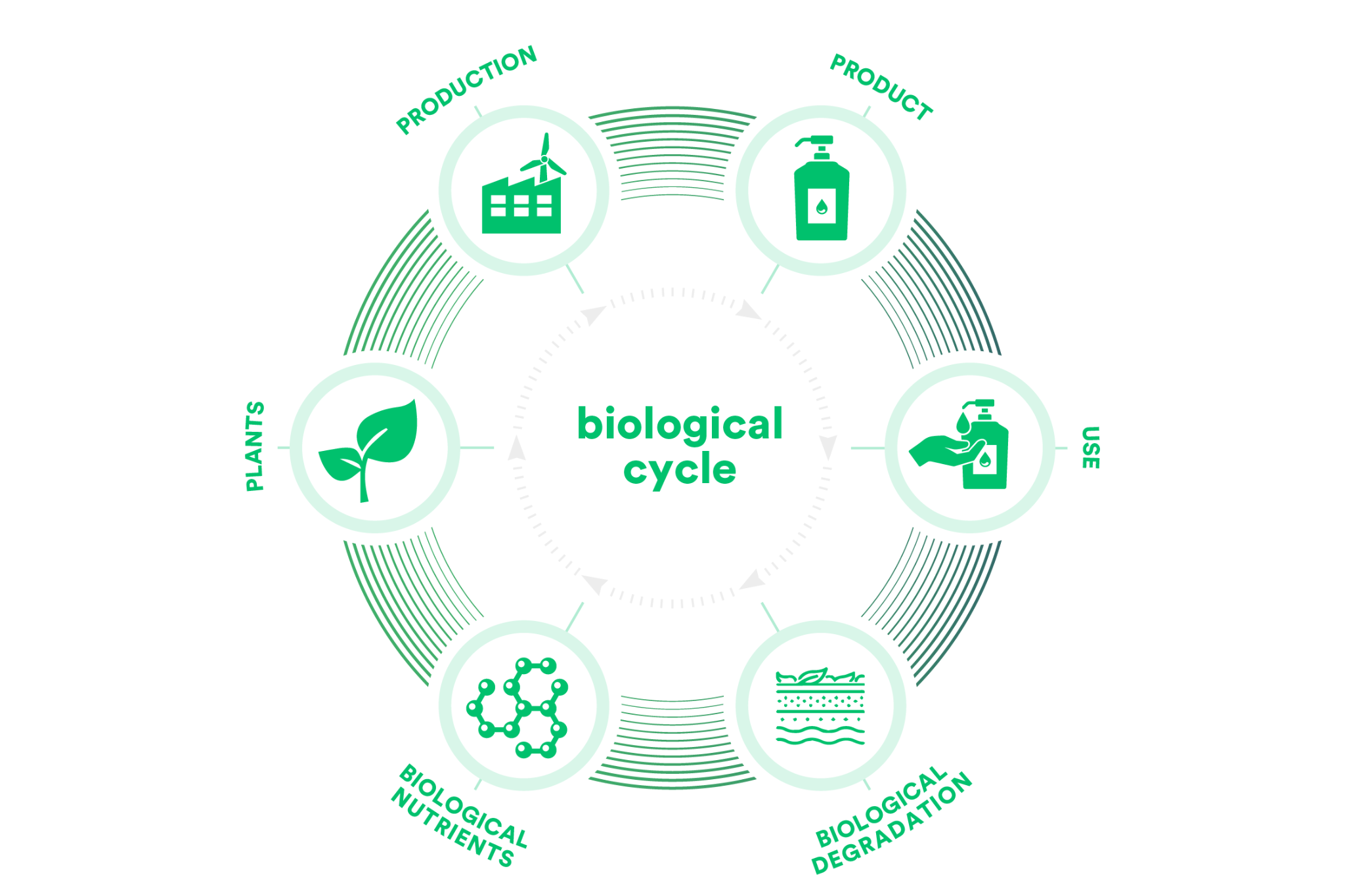

Cycling Pathways: Technical and Biological Cycles

A Cycling Pathway describes how a material is processed at the end of its use. Municipal recycling, home composting, aerobic biodegradation in wastewater, take-back and repair/remanufacture schemes by the manufacturer, are all examples of cycling pathways. Cycles can be technical or biological. We refer to a technical cycle when a product’s materials or parts are reprocessed for a new product use cycle via recycling, repair, refurbishment, remanufacturing or reuse. In other words, via one or more of the R strategies.

Conversely, in the biological cycle, materials or parts are released, and ideally reprocessed via composting, biodegradation, nutrient extraction, or other biological metabolic pathways. The Standard requires that companies designate all homogeneous materials in the product as either biological or technical, and identify appropriate cycling pathways for those materials once the product has reached the end of its current use cycle, in order to define the product’s technical and/or biological cycles.

Longevity as a Strategy

Integrated throughout the R-Strategies, is the key concept of longevity. The Cradle to Cradle Certified Product Standard promotes the longevity of products. From designers to purchasers, from marketing and sales to logistics, to the many suppliers and workers involved, the supply chain adds much value to products and there is so much that goes into bringing a product to market. Companies that commit to Cradle to Cradle principles are expected to deliver high quality and smart design, so that their certified products can be used for a long period by the user and possibly by successive users.

This comes back in the Standard as part of the Design Strategies on product longevity, and the shorter cycle R-Strategies of Reuse, Repair and maintenance. In a (modular) way, it also applies to Refurbishing, Remanufacturing and Recycling.

R-Strategies and Cradle to Cradle Certified®

The R-Strategies are inserted in the Standard within the context of technical cycling pathways. Hence a Cradle to Cradle Certified product intended for technical cycling needs to fit in one or more of the R-Strategies, in order to meet the requirements of the Product Circularity category. Below you can find further insights and some examples around each strategy.

#1 Reuse. This strategy is applied when a product is designed to be used more than once for the same purpose for which it was originally conceived. The product could be reused by the same owner or by another owner. Product as a Service (PaaS) is mentioned in the Standard as a design strategy that companies can adopt to stimulate reuse. As part of this approach, products are designed so that they can be rented, leased or shared by multiple customers. This approach, also referred to as Product-Service Systems, entails that products are offered in subscription models with services attached. Usually, the product is joined by more features or service contracts to repair or replace. Another reuse strategy is Prolonging the Use Phase of the Product, when the principles of longevity and durability are embedded in product design, and can be achieved through high quality materials and constructions, and design for purpose and re-purpose.

As products can be reused by membership, renting models or re-commerce, innovative solutions recently include the reuse of packaging too, as in the example from our community, Beauty Kitchen, which has launched a sector-wide reusable packaging scheme. Find out more here

#2 Repair. A product may present some defects after it has been used. At the design stage it may help to think about the behavior of the user and to deliver suitable repair services or repair kits to extend the lifespan of a product. According to the Cradle to Cradle Certified Product Standard, to achieve Silver Level certification for a product, companies have to provide examples of acceptable progress on “any work that has been done toward establishing a process or program for maintenance, repair, or refurbishing services, or partnerships that will allow for maintenance, repair, or refurbishing services”.

Modularity and Upgradability are design strategies recognized in the Standard that fit into this category, applied when a product is designed with parts that are replaceable, and replacement of these parts can be used toward the maintenance, upgrade, or expansion of the product.

An example from within our community is the Bang & Olufsen Beosound Level, designed with modularity in mind, so that it can be easily repaired and undergo personalization and style updates. Read more

#3 Refurbish. Some companies or service providers offer refurbishment options, either directly or through select partners. The product can be refurbished for the owner or re-sold to or rented by another customer. With this approach, a product can be returned to its original condition by replacing or repairing major components that are faulty or close to failure, and through cosmetic changes that update its appearance, such as cleaning, changing fabric, painting, or refinishing.

Ahrend’s Certified desk chairs are an example from within our community. The chairs are taken back for refurbishment and, once ready, go back to the market. The company also offers a Furniture as a Service scheme.

#4 Remanufacture. This process, more rigorous than refurbishment, involves disassembly and recovery at the subassembly or component level. Different to a refurbished product, a remanufactured product is restored to like-new quality not only in its appearance, but in its performance too, and parts are almost always rebuilt or replaced. In this case, functioning and reusable parts are taken out and rebuilt into a new product. This process includes quality assurance and potential enhancements or changes to the components.

The Standard refers to “Designed for Manufacturer Recovery and Reuse” as a strategy where a product is designed for a company’s take-back program or another company-based recovery initiative. The product must have been designed so that its components can be reused for other product applications within the recovery initiative. Companies that claim to adopt this design strategy as part of their Cradle to Cradle Certified product application, must present evidence of a program and/or partnership involved in the initiative. To achieve certification, for example at the Silver level, companies must present evidence of acceptable progress on work that has been done toward implementing a remanufacturing program for the product, or establishing partnerships that will allow for remanufacturing of the product.

Examples from our community include automotive supplier ZF and bathroom and kitchen solutions brand Grohe. Read their story in this article.

#5 Recycle. Recycling is defined as the process by which a material, after serving its intended function, is processed into a new material via mechanical or chemical transformation, and then added to a new material formulation in a different context. Current recycling systems provide mainly downcycled products, where materials re-enter the cycle at lower value. In the circular economy, the aim is to upcycle and bring products of equal or more value to the market through recycling. The related design strategies referenced in the Standard are:

Design with mono-materials: Making use of one raw material per product or detachable component, since most finishes, coatings and prints make it difficult to recycle.

Design for disassembly: Making sure that components are easy to detach.

Product Compatibility: designing the product for standardization or compatibility with other parts or products, so as to extend the use phase of the product and create more end-of-use cycling opportunities.

Recycling must always be a designated cycling pathway for Cradle to Cradle Certified products intended for technical cycles, because it is not possible to endlessly reuse and repair. To receive Cradle to Cradle Certified, companies need to show that it is possible to cycle the product via the chosen intended pathway(s), at least at the pilot scale (e.g., at small-scale under “normal” processing conditions). This may be demonstrated specifically for the product or for one or more similar products that are already being cycled in the intended pathways.

Examples from our community include Napapijri’s Circular Series, a line of outerwear produced entirely with one material, Econyl, created from chemically recycled polyamide (i.e. from fishnets from the ocean).

In conclusion, if you want to successfully start designing circular products, you need to be prepared for an extensive rethink of your internal systems and processes. As part of the Cradle to Cradle Certified® Products Program, you are also encouraged to collaborate with new partners who can help implement the relevant R-Strategies, and drive change in the entire ecosystem of your supply chain.