Beyond the hide: How Modern Meadow is engineering circular materials from the molecule up

Exploring Modern Meadow and its expertise of continuously advancing materials that unite performance, sustainability, and scalable production.

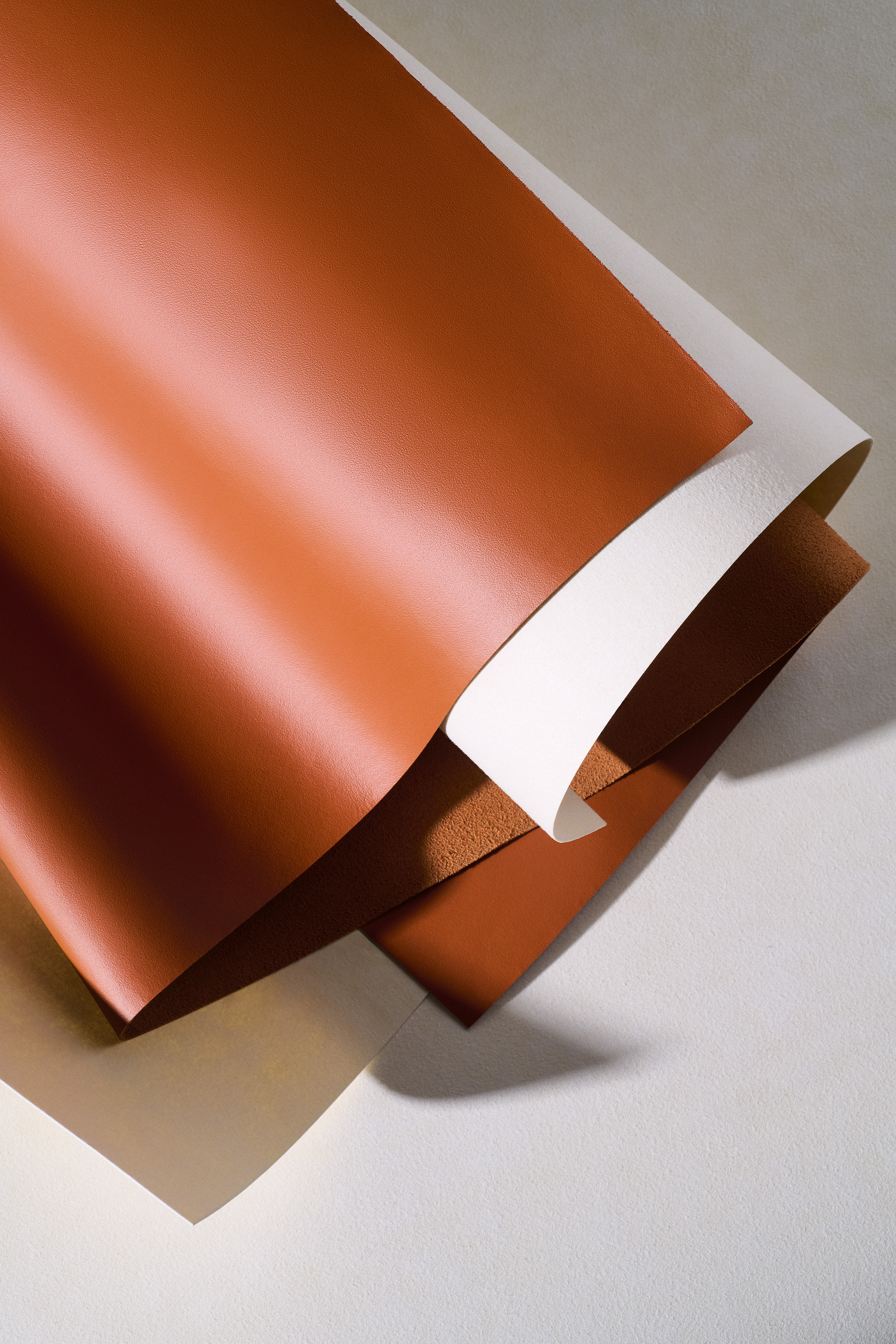

Modern Meadow has spent more than a decade developing next-generation materials that balance performance, sustainability, and scalability. The result is INNOVERA™: an animal-free alternative to leather made from soy protein, recycled rubber, and renewable biopolymers. Designed to meet the needs of today’s tanners, the material performs like leather but is built for circularity from the start.

At the center of this system is Dry White, the Cradle to Cradle Certified® precursor canvas used to produce INNOVERA ™. This canvas acts as the foundation for downstream finishing, giving tanners a familiar starting point while shifting the impact of production upstream. By working within existing tanning infrastructure and reducing the need for customized workflows, Modern Meadow is addressing one of the biggest hurdles to circular material adoption: practical use at scale.

This approach means brands and tanners don’t need to overhaul their tools or retrain teams - they can start with what already works and build toward something better.

As Modern Meadow CEO David Williamson, PhD, shared, “It’s one thing to make a circular product that works in the lab. It’s another to make one the industry will actually use.”

Built for the loop

Modern Meadow didn’t adapt INNOVERA™ to meet sustainability goals – circularity was part of the blueprint from day one. The material is designed for disassembly, with each component able to re-enter the supply chain as raw input for new Dry White canvas. This end-of-use strategy is embedded at the molecular level, ensuring the material doesn’t just perform during use – it’s built to perform across its entire lifecycle.

Its nylon scaffold is produced from recycled rubber, primarily sourced from used car tires, giving new purpose to a common waste stream. The biopolymer mix comes from corn and rapeseed oil waste – agricultural byproducts that are repurposed rather than discarded. The soy protein is supplied by accredited US-based partners who provide full traceability, ensure crops are non-GMO, and follow regenerative agricultural practices. These inputs were selected not only for performance, but also for their alignment with ingredient health and long-term circularity.

Together, these ingredients form a system intended not just to reduce environmental impact, but to extend the life of the material itself. INNOVERA™ is designed to be recovered, reprocessed, and remade.

“Rather than send INNOVERA™ to a landfill when users are done with it, the material can be stripped and reused to create the next batch,” Dr. Williamson said. “That’s what circularity looks like in practice.”

Inside the certification: How INNOVERA™ was built to meet the standard

INNOVERA™ wasn’t designed first and certified later. Cradle to Cradle Certified® requirements were part of the development process from the start, guiding choices around raw materials, supply chain setup, and production infrastructure. Rather than working around the standard, Modern Meadow used it as a framework for building a material that could align performance with circularity from the molecular level up.

The certification process focused on two core categories: ingredient health and product circularity. Each requirement was treated as a design tool to shape better systems. This helped refine not only the composition of the Dry White canvas, but also the traceability and transparency needed to manage those systems over time.

Cradle to Cradle Certified® also adds consistency to how INNOVERA™ is scaled and implemented. It brings structure to supplier evaluation, supports transparency in material claims, and reinforces the science behind the product's environmental profile. This alignment strengthens collaboration across the value chain and supports more informed decision-making for brands and manufacturers alike.

INNOVERA™’s certification is not an external stamp placed on a finished product. It’s an internal design logic that shapes how the material performs, circulates, and evolves.

What’s next for INNOVERA™: Scaling without compromise

Modern Meadow is focused on scaling INNOVERA™ in ways that stay true to the material’s original intent. That starts with expanding production through a decentralized model, placing manufacturing hubs closer to where brand partners operate. This approach reduces transportation impacts, increases flexibility, and supports faster adoption without creating unnecessary complexity.

At the same time, the team is investing in new material functionalities that go beyond performance basics. Research is underway to embed qualities like abrasion resistance and flame resistance directly into the material, using the same circular design logic that shaped INNOVERA™ from the start. These additions are meant to expand the material’s reach across industries while maintaining ingredient health and end-of-life recoverability.

As the roadmap continues to evolve, every improvement is assessed not just for how well it works, but for how well it fits within the system. The focus remains on progress with accountability, ensuring that growth does not come at the cost of circularity.

Advice for newcomers to Cradle to Cradle Certified®

“Cradle to Cradle principles should be at the core of material development. You should be designing and engineering the material to be sustainable and circular from the start,” shared Dr. Williamson. “You also need to understand how your material fits into the broader ecosystem. Will it replace an existing process, co-exist with it, or create a new path entirely?”

For companies starting out, clarity and communication matter. Speak to stakeholders in a way that connects with their priorities. Brands value scalability and consistency, while manufacturers focus on quality and functionality. Tailoring the conversation helps make circular innovation relatable and actionable.

Data brings credibility. Lifecycle assessments give measurable proof of impact and make circular performance visible. As Dr. Williamson explains, every company’s path will look different, but designing with intention, communicating effectively, and grounding decisions in data are strong first steps toward success.

Forward with function: INNOVERA™’s real-world impact

As more brands seek circular solutions they can actually use, INNOVERA™ stands out not only for its credentials, but for how easily it fits into the systems that already exist. From supply chain flexibility to localized manufacturing, Modern Meadow has designed a material that lowers the threshold for adoption without lowering the bar on performance.

“Making a material that works in theory isn’t enough,” Dr. Williamson shared. “It has to meet real production needs and deliver value across the chain.” INNOVERA™ does both - bringing together ingredient transparency, production efficiency, and circular end-of-use options in one platform.

This is not a concept looking for an application. It’s a practical material, grounded in science and ready to scale.